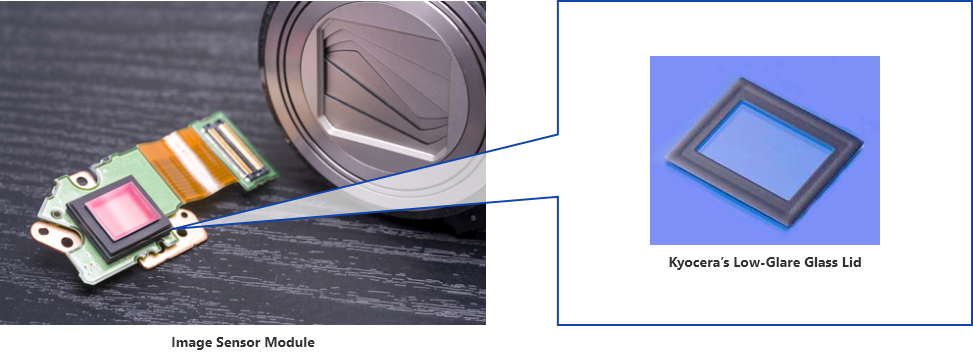

Features of Kyocera’s

Low-Glare Glass Lid

Functions required for automobiless are continuously evolving. As such, accurate sensing of pedestrians, vehicles,

and obstacles is essential to ensure the safety and security of Advanced Driver Assistance Systems (ADAS) and Autonomous Driving (AD) systems.

However, “noise” (glare, etc.) from in-vehicle cameras is a risk factor for higher precision sensing.

Kyocera developed the “Low-Glare Glass Lid” with printed light-shielding epoxy to reduce these sensing risks.

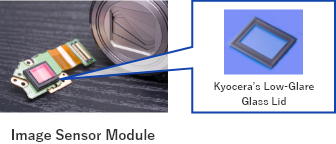

Low-Glare Glass Lid (Cover Glass with Light-Shielding Epoxy)

Anti-Reflection Shielding Blocks Light Transmittance and Absorption

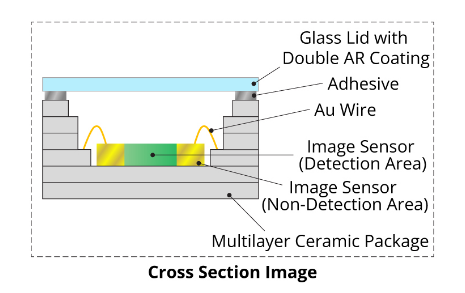

Kyocera’s Low-Glare Glass Lid is effective against the glare on image sensor modules. A Light-Shielding Epoxy is printed on the glass to shield light transmittance and help light absorption for anti-reflection. As a result, there is no need to assemble a Metal Shading Plate, which helps reduce the number of assembly process steps and overall cost.

Unexpected and unnecessary incoming light on image sensors can create “noise” (glare, etc.) which causes sensing defects. Kyocera’s Low-Glare Glass Lid cuts unnecessary light in the image sensor’s detection area and absorbs diffused reflection light within the image sensor to improve safety.

※All images are for illustrative purpose only

Technology Comparison

of Glare Reduction

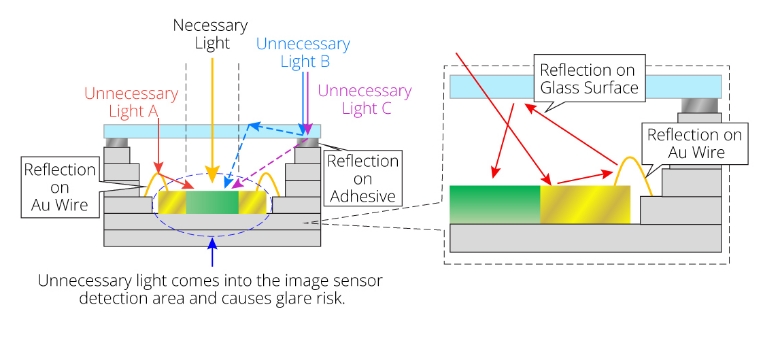

Glare occurs when the image sensor detects unexpected light at various angles.

Effective countermeasures add a function inside the device to block unnecessary light.

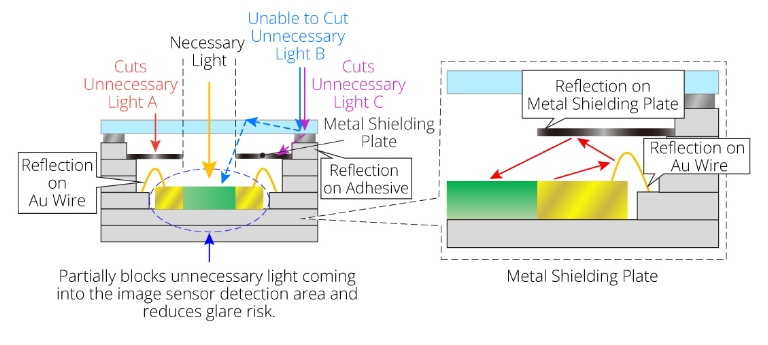

No Glare Reduction Countermeasure or Metal Shielding Plate

-

1

No Glare Reduction Countermeasure

Unnecessary Light

(Noise) Prevents

Accurate Sensing

Without any countermeasures, the image sensor detects noise caused by unnecessary light and reflection light.

-

2

Using Metal Shielding

Plate

Metal Shielding Plate

Not Adequate

Countermeasure for Unnecessary Light

Some unnecessary light will still go into the image sensor with a metal shielding plate. As a result, a metal shielding plate is not an adequate countermeasure to prevent noise in the image sensor.

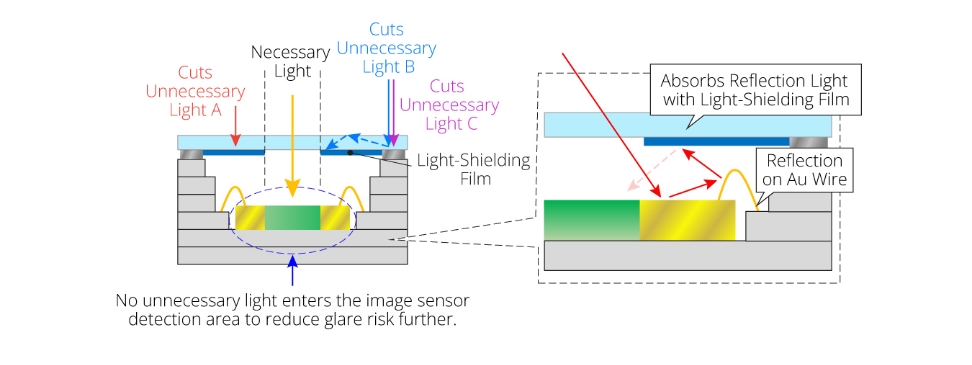

Light-Shielding Concept (Light-Shielding Film)

Reduces Reflection Light

Kyocera’s Light-Shielding Film has a lower reflectivity than a metal shielding plate, so it can better reduce unnecessary reflection light and glare.

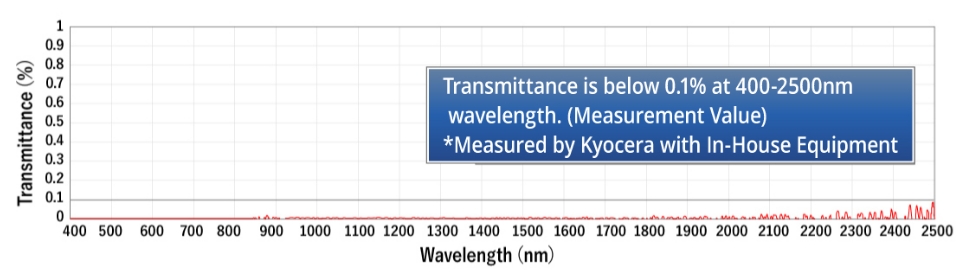

Superior Light Shielding with Kyocera’s Original Materials

Kyocera’s Low-Glare Glass Lid uses a Light-Shielding Epoxy printed on the glass surface to shield light transmittance. As a result, the Low-Glare Glass Lid has <0.1% transmittance at 400-2500nm Wavelength.

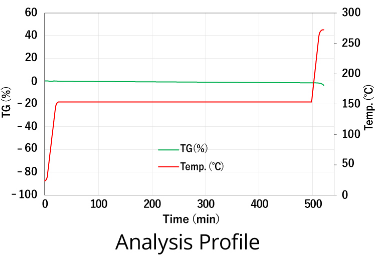

Minimum Outgassing for Safe Sealing

Based on TG-DTA Analysis results, outgassing is minimal. As a result, it is safe to use as part of a semiconductor device.

*TG-DTA Analysis:

Analysis to perform TG (Thermogravimetry) and DTA (Differential Thermal Analysis) at the same time on a single sample

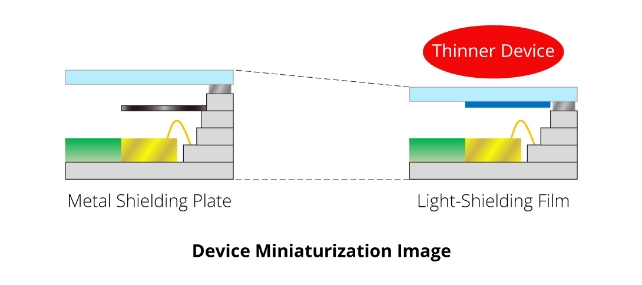

Eliminates Metal Shielding Plate for Device Miniaturization

When using a metal shielding plate, extra space is required to mount the plate inside the package. However, by integrating the Light-Shielding Film with the glass, no extra space is needed. As a result, overall device thickness is reduced, contributing to device miniaturization.

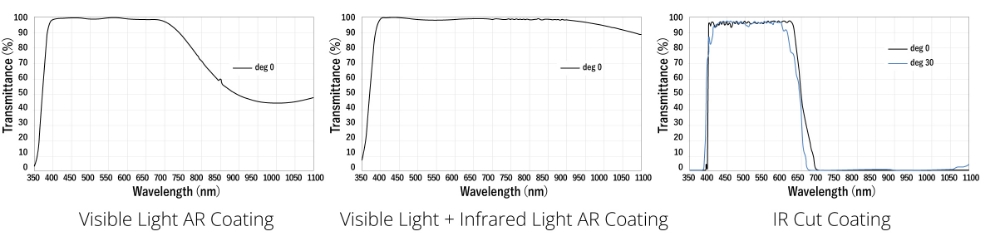

UV Epoxy Seal and Custom AR Coating

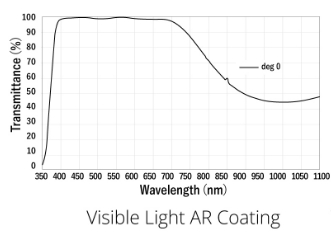

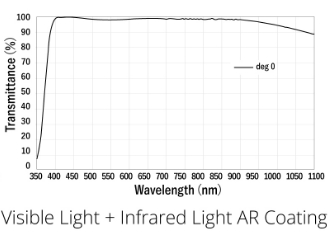

A standard UV Epoxy Seal on the image sensor needs to transmit UV Light (365nm). Kyocera’s custom AR Coating can transmit over 50% of UV light, compared to a normal AR Coating, which only transmits 20% of the UV light. As a result, Kyocera’s solution improves the productivity of the UV seal process.

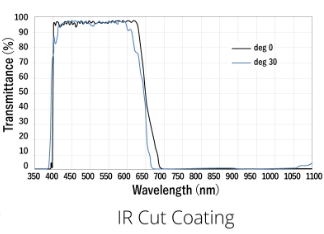

In addition, our experience manufacturing glass lids for high-end commercial cameras and industrial machine vision allows us to design and apply custom optical thin films on the glass lid, such as Anti-Reflection Coating (AR Coating), IR Cut Filters to cut infrared light, or Band-Path Filters to pass specific wavelengths, depending on the application.

Please contact Kyocera

for more details.

- Offer Various

Glass Lid Material -

Kyocera can offer the best glass lid material depending on the attaching surface.

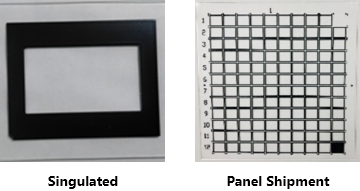

- Different Form of Shipment

-

Kyocera can offer different shipping forms to fit assembly equipment or environment.